- Home

- About Us

- Products

- Ball Valves

- Plug Valves

- Butterfly Valves

- Gate Valves

- Globe Valves

- Check Valves

- Severe Service

- API 6D Valves

- Steam Engineering Products

Butterfly ValveBall ValveFloating Ball Valve- 1 Piece Design

- 2 Piece Design

- 3 Piece Design

- Jacketed Ball Valve

- Cryogenic Ball Valve

- Lined Ball Valve

- ON OFF Ball Valve

- Metal Seated Ball Valve

Floating Ball Valve1 Piece Design

2 Piece Design

3 Piece Design

Jacketed Ball Valve

Cryogenic Ball Valve

Lined Ball Valve

ON OFF Ball Valve

Metal Seated Ball ValveTrunnion Mounted Ball Valve- Double Block & Bleed Ball Valve

- Twin Isolation Ball Valve

Multiport Ball Valve- 3 Way

- 4 Way

Top Entry Ball ValveFully Welded Ball ValveRising Stem Ball ValveHIPPS Service Ball ValvePlug ValveSleeve Plug ValveJacketed Plug ValveLubricated Pressure Balanced Plug ValvesDouble Block and Bleed Plug ValveTwin Isolation Plug ValveSWRO Plug ValvesLined Plug ValveMulti Port Plug Valve- 3 Way Plug Valve

- 4 Way Plug Valve

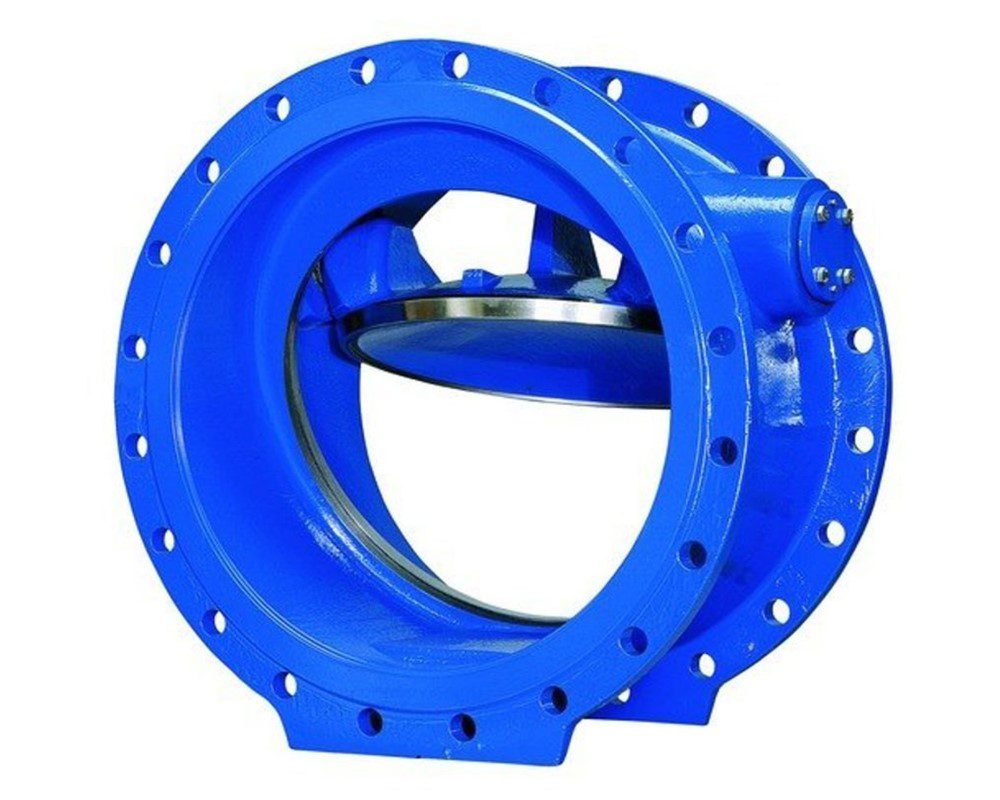

Butterfly ValveResilient Seated Butterfly ValveDouble Offset Butterfly ValveTripple Offset Butterfly Valves(TOBV)Fabricated Butterfly ValvesLined Butterfly Valves - Services

- Blog

- Contact Us

Call Any Time

+91 95588 98767